Tech Info and hints

New addition: 1/31/2001

![]() Chevette cams &

rockers/springs

Chevette cams &

rockers/springs

Below are things that were sent in e-mails to me, describing things that were done working on Chevettes:

V-6 Chevy Motor...

How come no interest in the Chevy 229/262 V6 engine in a Chevette. I built a 79 Chevette with the 229 and for 5 years I had lots of fun with it. I used a 229 from an 81 Monte Carlo with the automatic from the Monte. Talk about an easy swap. I even used the original cast iron exhaust manifolds from the Monte in my swap. Yes they do fit. All the electricals hooked up except the oil sender. I had to use a reversing relay to get the oil light to work right. The distributor and throttle body were replaced with pieces from a 79 without computer control. The only custom pieces were the radiator ( It mounted in basically the same place with an electric fan in front of the radiator, the drive shaft ( it had to be shortened) and the steering shaft (I used a double u joint for correct operation).

This car was a blast to drive and took a whole bunch of people by surprise. I would hope others would use the Chevy V6 as the conversion was real easy and Chevy parts are easier to find than a Buick, besides a Chevy belongs in a Chevy.

229/262 Chevy V6 in a Chevette, here is how I did it.

1. Remove and discard the old frame mounts for the engine.

2. Get a Chevette automatic transmission crossmember and turn it 180 degrees. Elongate/lengthen the tranny mount holes 3/4 " closer to the front of the car. I am not sure any more what kind of auto tranny I had, this measurement might change.

3. Make a new frame mount for the engine by looking at this example. This mount goes on the ledge of the subframe in the engine bay. Get enough engine clearance from the crossmenber by putting a short piece of 2x4 beneath the oil pan. Put the frame mounts into approximate position and lower the engine into the engine bay. Be sure to remove the distributor first or you will bust in lowering the engine in. Center the engine, leaving enough room for the distributor at the firewall. Drill the holes for the engine mounts into the frame mount. Now drill through the subframe and frame mount. You will need some really long bolts for this.

4. The oil pan sump has to have 1-1/2" removed to clear the steering. You also have to move the oil pump pickup in the oil pan after you shorten the pan for the pickup to fit in the oil pan. The dipstick does not have to be modified.

5. The automatic trans has to have the mounting ears that stick out to the side ground off.

6. Discard the exhaust heater control valve on the exhaust manifold.

7. Trim about 2 inches off the alternator adjustment at the top to get the hood to close.

8. Get a new radiator built in 4 core that is approximately 50% greater square area that came with the original 229 V6. Install the largest electric fan you can fit in front of the radiator, 2 would be better. My 229 had a long water pump. Maybe a short water pump will let you mount the fan on the engine side.

8. The new radiator mounts about 1 inch forward and down from the original lpcation.

9. I used double u-joints to get the steering to work.

10. All the elctricals hooked up except the oil sender. I had to use a relay to reverse the signal to make the oil light come on with no oil pressure.

11. To get the original exhaust manifolds to work I built them out of flex tubing and later had an exhaust shop duplicate them in tubing. The exhaust was ok on the drivers side, but it had to go through the hole in the subframe under the passengers feet on the other side. You have to make this connection a slip fit with a regular muffler clamp so that you can insulate this area. You must insulate the pipe going through this hole and near the floor boards or you will have a carpet fire like I did. Also I used the Y pipe from the original set up to connect the two sides for a single exhaust. There is no room for dual exhausts.

12. To get to the right ride height I used adjustable overload springs that surround the front stock shocks.

13. I used a Chevette tranny shifter for the auto trans and modified the shift arm to fit.

14. I had a custom driveshaft and speedo cable made to hook those up correctly.

15. The heater hooked directly into the 229 using new hoses for proper length.

16. The large red wire that used to go to the 4 banger distributor will attach to the V6 with a change of connector.

17. You will have to use a carburetor from a non-computer 229 and non computer distributor.

I did not modify the firewall or fenderwells in this swap.

This swap was done in 89. I hope that I have remembered all the details. Good luck.

From: Corvair123@aol.com

Head Rebuild

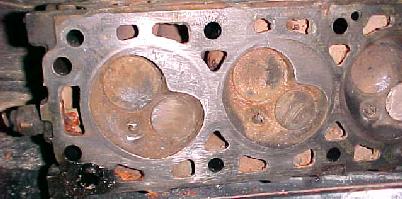

Regular Head

i went ahead and rebuilt that head with the heart shaped chambers(you dont know if you dont try) i've only found 2 styles and this may be the h.o.head listed for 1980 only and said to provide an extra 7 hp.i know it does'nt sound like much but heck thats 10 percent.i found some honda civic valve springs that will work well inside the stock ones and should eliminate any valve float.that,port matching and a casting cleanup should complete the head.i may have found a local guy to regrind the cam.the only failures we've had are rods.three engines broke them off just below the small end(generally number three cylinder.....why?)shot peen and magnaflux may be the answer.got an extra carb?pull the jets out...you'll notice one large and one small.run both large ones (it made a noticable improvrment)this is the first time i've built one of these engines as we've been running junk yard dogs ourselves and with some patience and tuning we've had competitors (mostly mustang guys) accuse us of cheating"because no chevette could be that fast".stay in touch, have fun,and i'll keep you posted on my 200 dollar rebuild

Heart Shaped..H.O.

The first pic (below) shows the difference in combustion chambers. I haven't measured them but you can see the heart shaped chambers will produce a higher compression ratio. The second picture (below) shows the honda civic valve springs I'm using inside the stock ones.

Arrows denote differences between standard and h.o. head.

Click on pic for larger view.

A...................."2" cast on boss "23"cast on boss

B....................boss at temp sender boss at temp.sender

not machined machined

C.....................casting#466395 casting#14071110

D.....................casting#A220 casting#D216

I found a 1979 motors repair manual which mentioned the h.o.engine but listed no horsepower ratings or engine codes.

These codes would sure make hunting a lot easier. The stats in this book also listed oil pressure as 40 p.s.i for standard engine and 55 p.s.i.for h.o. engine.

THE HEART SHAPED CLOSED CHAMBER HEAD IS ONLY FOUND ON THE 1980 MODEL

CHEVETTE W/ THE ENGINE PAINTED ORANGE INSTEAD OF BLUE FROM THE FACTORY.

Dual Exhaust Manifold info:

Chevette Rally 1.6 liter "O-code" dual outlet exhaust manifold

Part number 14002409 Part has been discontinued and no longer in stock.

Looks like this item will be a wrecking-yard-only item, unless someone checks an old GM parts clearinghouse-type outlet.

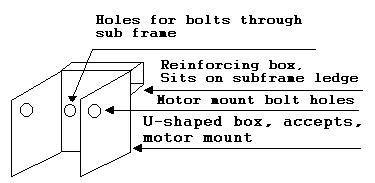

Try this for the frame mount for the 229/262 V6 conversion.

This u shaped box, with a box welded on, sits on the ledge of the subframe in the engine compartment. The engine mount fits in it and a long bolt goes through the frame mount and engine mount.

Brakes

Front discs brakes from an Izuzu Impulse bolt in. Use the whole spindle and tie rod ends. Rear discs require welding a new front mount for the Izuzu rear end and a driveshaft, but its almost a bolt in. the control arms, panhard rod and shocks are in the same place. An I-Mark rear end with a repositioned panhard rod might be easier, but I am not sure if the Impulse brakes fit in on the smaller axles.

Gauges

If you happen to find a rallye guage package, Haynes' repair manual has a schematic to re-pin the plug so it will work.

If you want to really mess with peoples minds, try replacing the stock speedometer with a 160 MPH speedometer. I did. I used a Stewart Warner 160 Speedo and installed it where the stock one used to be. Just remove the stock Speedo and get a large hole cutting drill like they use to drill for door locks/handles in the size of the Speedo you want to install. Use the

stock Speedo cable hole as your center. I had to make up a stiff inner plastic mount to hold the front of the Speedo to the inside of the instrument cluster. The rear of the Speedo was held by the plastic of the instrument cluster. You will have to have a new Speedo cable made to match the new speedometer.

Be sure to mark where all the electrical PC wiring goes, so that after you cut the PC wiring you can rewire/solder new circuit wires in place. You can get some real reactions when someone sits in the drivers seat and sees a 160 MPH Speedo where the original 85 was. Have fun with this one.

Rims & Rear End

Impulse wheels look good on a C'Vette. and the Impulse rear end is about 1.5" wider. use a pre-turbo rear end not the 4-link.

5 Port TVS Tech Tip

Trying to bring my Chevette back to life has caused me to find one problem after another with it. My 5 port TVS (Thermostatic Vacuum Switch) went bad so I took it off and ordered another and (since this is New Years Day) what better way to spend the day than to bust the old one open and figure out what the heck it does. After all, it was either that or go shopping at the mall with the wife. :(

I originally found the TVS to be bad when I wasn't getting vacuum to the transmission control switch. I sprayed some WD-40 on the base of the black plastic tower with all the tubes

sticking out of it and then hooked up a piece of vacuum line to the bottom tube. Blowing into the line I saw the WD-40 bubbling all around the base of it. That is a vacuum leak, my friends.

Tracing thru the TVS vacuum connectors I also found my vacuum regulator valve was bad. That is probably the reason why my timing always seemed to be weird. Where the heck I'm gonna find a new one of those gizmos I haven't a clue (dealer? $$$).

Anyway, in case anybody ever needs to troubleshoot vacuum lines to and from the TVS, this is how the 5 port TVS routes vacuum all around the emission system for a Chevette. This is for a

1985 Chevette automatic with no air conditioning. Your milage may vary.

Vacuum hose connections on the 5 port TVS looking at it from the front. The TVS has numbered ports on it.

1

*

3 * *4

2*

5*

#1 - Goes to the vacuum delay valve, left side (manifold vacuum).

#2 - Goes to vacuum delay valve, right side (manifold vacuum). It is always receiving manifold vacuum.

#3 - Goes to the EGR valve and tees off to the air cleaner TVS switch (ported vacuum).

#4 - Goes to the charcol canister and tees off to the transmission vacuum control switch (ported vaccum).

#5 - Goes to the EGR port on the carb and tees off to the other side of the air cleaner TVS switch (ported vacuum). It is always receiving ported vacuum.

It is important to remember that inside the TVS #5 connects vacuum to # 3 and #4 ONLY (ported). In addition, the TVS ONLY connects vacuum between #2 and #1 (manifold). #1 and #2 are completely separate from the others. Wheather the engine is cold or hot the TVS is always receiving ported vacuum in #5 via the carb EGR port.

Once the TVS opens, ported vacuum is being passed to the EGR valve/air cleaner TVS (#3) and the charcol canister/Transmission switch (#4). Likewise, #2 is always receiving manifold vacuum via the delay valve which is in turn directly connected to the manifold vacuum fitting, but no manifold vacuum is being supplied to the other side of the delay valve (#1) until the TVS opens. Once this happens distributor advance is then regulated by the interplay of ported and manifold vacuum in the vacuum regulator valve that connects to the delay valve. Notice that since #5 is always receiving ported vacuum and that it tees off to the air cleaner TVS, and also the other side of the air cleaner TVS connects to #3. This means that if the air cleaner TVS is open (high air temperature) it will bypass the 5 port TVS and send vacuum to the EGR valve anyway. If you are having a problem with the EGR valve you might want to check for proper operation.

Torque Converter Lockup Troubleshooting

I had a problem with getting torque converter lockup in my 1985 Chevette automatic (TH180C) without air conditioning. This is how I troubleshot my problem. It might help you, it might not.

First, the components that make up the necessary parts to perform torque converter lockup are:

1. The brake switch.

2. The transmission vacuum switch.

3. The TCC solenoid.

The transmission vacuum switch is located under the plastic cover in the rear corner drivers side of the engine compartment. It covers the electrical connectors from the engine bay to the dash and fusebox inside the car.

Take the cover off and you will see a small square device with a round disk in the middle of it. This is the transmission vacuum switch. You will notice that the switch has a vacuum line running out of the top of it. This leads to the charcol canister (it also has a vacuum delay gizmo in between). The switch uses ported vacuum that comes from the 5 port TVS (thermostatic vacuum switch) screwed into the intake ported next to the thermostat.

The switch works like this:

When engine temperature has risen to the point where the TVS can now pass ported vacuum, the transmission control switch is then energized and a signal is sent that the engine is now in "cruising mode" (which means high ported vacuum). When you step on the gas to accelerate quickly, ported vacuum drops and disengages the switch. When normal cruising is encounted once more the switch engages again. Pretty simple divice.

Underneath the switch is a connector with a blue wire and two green wires. The blue wire comes from the brake switch and one green wire goes to the transmission to activate the clutch. The other green wire goes to terminal 'F' in the computer diagnostic connector. The 'F' connector is the one on the extreme left, top row looking at it from the front.

So it works like this:

Engine temperature is up, TVS opened, transmission vacuum switch is closed, your foot is off the brake and the clutch then engages. The circuit flows in series from the brake switch to the vacuum switch then to the clutch. The extra green wire only goes to the diagnostic terminal for troubleshooting purposes. That 'F' connector is really handy. This is what I did:

I got out my trusty $10 mulitmeter and set the range to 12v DC. I then stuck the postive lead into connector 'F' and the negative lead into connector 'A' which is a ground connector (the 'A' connector is the slot on the top row, far right). You can use a simple continuity testor here if you like. I then unplugged the electrical connector from the transmission vacuum switch and jumped the connector. This left it in the 'on' mode no matter what. Then got in the car and turned on the ignition. With my foot off the brake I saw 12 volts which is what I should have. When I stepped on the brake I saw 0 volts. My brake switch was working correctly. Actually it was a little "sticky" and I adjusted it a bit.

Then I reconnected the transmission switch and went for a drive with the multimeter still plugged in. After the engine got hot and I was in cruise I should have seen the switch close and 12 volts appear on the meter. I didn't. I was obviously not getting vacuum to the switch. In fact I wasn't getting ported vacuum anywhere. I had a bad TVS. That could explain a lot!

Especially engine timing problems. :)

To make sure about the vacuum switch, I plugged the switch directly to manifold vacuum from the manifold vacuum connector that had one plug unused. When I took it out for a drive again the switch acted correctly, passing voltage under high vacuum and disconnecting under low vacuum. Of course, you can't leave it connected this way under normal driving since the switch uses ported vacuum to operate correctly under all conditions. If the brake and vacuum switches check out okay you probably have a bad TCC solenoid. You'll have to drop the transmission pan and change it.

Well, that's my story and I'm sticking to it.

For what it's worth...Copyright © 2001 by Stanley J. Shenko

Misc. Tips

- CHEVETTE MANUAL TRANS. HAS TWO DIFFERENT FLYWHEELS ONE WEIGHS 23LBS FROM

FACTORY, ONE WEIGHS 18LBS. THE LIGHTER ONE WILL MAKE YOU QUICKER ON SHORT

CIRCLE TRACKS. (ESPECIALLY IF YOU TAKE AN ADDITIONAL 5LBS OFF OF IT)

- IF YOU KNOW ANYONE WANTING THE 411 REAREND THAT I LOOKED FOR FOR SO LONG.

I HAVE AN EXTRA ONE. IT IS EXPENSIVE $650.00 E-mail:TIMBERMOUNT@aol.com

-MR GASKET MAKES AN ELECTRIC WATER PUMP KIT FOR A V/8. SUPPOSEDLY IT ADDS UP

TO 20HP ON A V/8. I DON'T KNOW WHAT IT ADDED TO OURS BUT IT DID BOLT UP

SIDEWAYS WITH A FEW SHIM MODIFICATIONS.

THE ALTERNATOR AND BRACKET MUST BE OFF FOR IT TO WORK. YOU ALSO HAVE TO MOVE

THE RADIATOR FORWARD 1" TO CLEAR THE FAN.

-DON'T DO LIKE I DID AND ALSO SPEND AN EXTRA $100.00 BUYING AN ELECTRIC FAN.

A LIGHT WEIGHT FAN WILL BOLT UP TO WATER PUMP PULLEY AND RUN OFF OF THE SAME

ELECTRIC MOTOR.

Questions?

Anyone else putting a 2.8 V-6 in a chevette?

Will Edelbrock headers for an S-10 pick-up fit this swap?

Other than that, I am looking for a cheap posi-traction for the Impulse rear end (pre-turbo). Opel?

Anyone know how to fix a stock tachometer to work with a V-6?

Questions from E-mail: ChevetteLE@aol.com